Technological Innovation In Ensuring The Quality Of Power Fitting Components

In the long-term operation and maintenance of power transmission lines, the performance of metal components directly affects the safe operation of the entire power system. With the continuous development of science and technology, power line hardware testing technology is also constantly improving, evolving from the traditional manual inspection method to a multi-dimensional and multi-level comprehensive evaluation system.

The combination of UAV remote sensing imagery and deep learning algorithms provides a new approach to monitoring the condition of power transmission lines. High-resolution image data, combined with computer vision technology, allows for precise location of defects in various components, significantly improving the coverage and accuracy of inspections. Compared to traditional foot inspections, this method reduces labor costs and eliminates the safety hazards of working at heights.

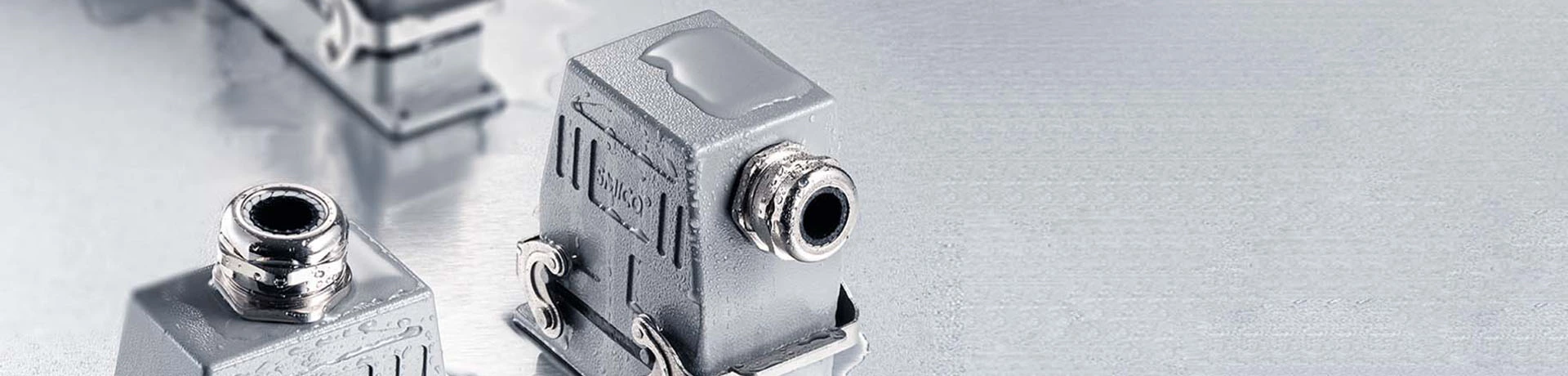

Mechanical performance testing, corrosion resistance assessment, and electrical performance testing constitute the core framework of modern overhead line fittings testing. Specialized instruments such as tensile testing machines, salt spray chambers, and temperature cycling testing equipment are widely used in laboratory testing, evaluating the actual performance of components under complex operating conditions through standardized testing procedures. This test data provides a scientific basis for product quality certification and fault prevention.